Services

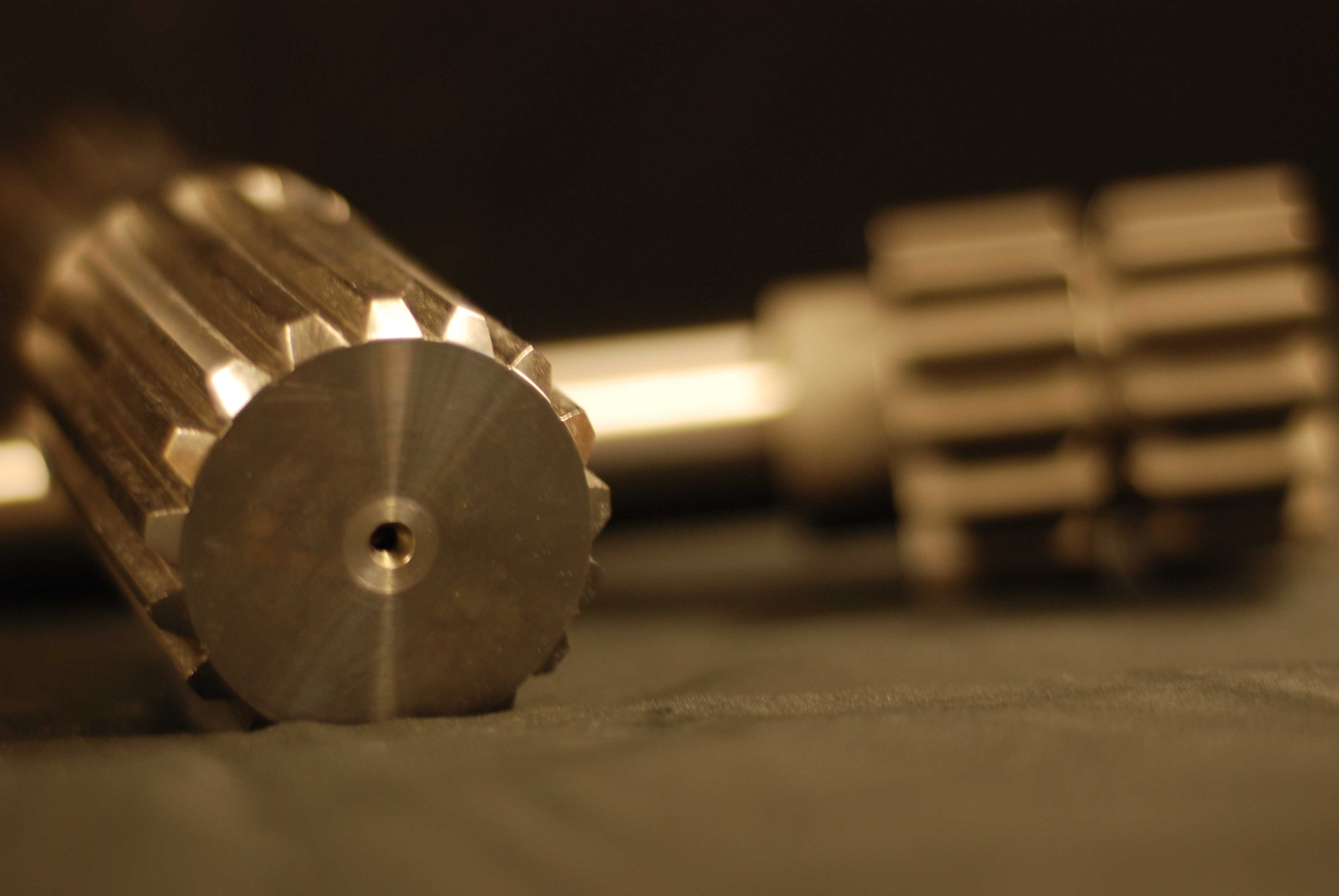

At Omni Gear, we don’t fill orders from inventory; we manufacture quality gears in-house to meet your exacting specifications. We manufacture in a large selection of materials including brass, bronze, plastic, fibre and alloys, and we’ll cut teeth on your blanks to your specifications.

Read on for more info on our capacities and facilities, request a quote, or see our Technical Gear Info page for detailed PDFs.

Capacities

We rigorously inspect each gear during and after production to ensure it conforms to your prints or sample parts.

- Spur Gears: .5 – 80 DP, up to 64″

- Helical Gears: .5 – 80 DP, up to 64″

- Cluster Gears: .5 – 80 DP, up to 36″ OD

- Internal Gears: 2 – 80 DP, up to 36″ OD

- Sprockets: #25 – #200 chain, up to 64″ OD

- Involute Splines: 2.5/5 – 40/80, up to 56” Long

- Straight Sided Splines: 4, 6, 8, 10 teeth, up to 56” Long

- Timing Belt Pulleys: up to 64″ OD

- HTD Pulleys: up to 64″ OD

Gear Cutters

- 1 – Hera 350 CNC Hobber

- 1 – Pfauter PE500AW CNC Hobber

- 1 – Fellows FS400-125 CNC Shaper

- 2 – 16×16 Barber-Colman CNC upgrade Hobber

- 2 – CQMT H500 Hobbers

- 1 – H1600 CQMT Hobber

- 1 – H800 CQMT Hobber

- 1- Pfauter P900 Hobber

- 1 – 48″ Hobber

- 2 – 24″ Hobber

- 3 – 14″ x 15″ Barber-Colman Hobbers

- 1 – 14″x 30″ Barber-Colman Hobber (rebuilt 10/15)

- 2 – 16″ x 16 Barber-Colman Hobbers

- 1 – 22″ x 15″ Barber-Colman Hobber (rebuilt 10/15)

- 2 – 16″ x IS” Barber-Colman Multi-Cycle Hobbers

- 1 – 16″ x 36″ Barber-Colman Multi-Cycle Hobber

- 1 – 16″ x 56″ Barber-Colman Hobber

- 3 – 6″x 10″ Barber-Colman Hobbers

- 2 – 6″ x 16″ Barber-Colman Multi-Cycle Hobbers

- 1 – #3 Barber-Colman Hobber

- 1 – Lees-Bradner Thread Mill

- 3 – 20-4 Fellows Shapers

- 2 – 10-4 Fellows Shapers

- 1 – 10-2 Fellows

- 3 – 7″ Fellows Shapers

Gear Grinder

- Reishauer RZ400 CNC Gear Grinder

Lathes

- Doosan Puma VT900 VTL

- 2- Okuma Crown

- 1 – Okuma Genos (new 9/12)

- 1 – Okuma Genos L250E (new 9/14

- 1 – Okuma LB3511

- 1 – 14 x 40 Toolmex

Grinders

- 1 – Clausing 12 x 24 Surface Grinder

- 1 – Arter Rotary Grinder

Secondary

- 1 – Haas TM2 CNC Mill

- 1 – Haas VFI CNC Mill (new 9/12)

- 2 – Haas VF2 CNC Mills

- 1 – Haas Vf3 CNC Mills with 4th Axis

- 1 – Acme #625 Broach

- 1 – Four Spindle Drill Press

- 1 – Bridgeport Mill

- 1 – 16″ HE&M Saw (new 5/15)

- 2 – DoAll Saws

- 1 – Meco CNC Slotter

- 1 – Morrison Keyseater

- 1 – Mitts & Merrill #3 Keyseater with Tilt and Indexing Table

Inspection

- Dapra Laser marking system

- 1 – Aberlink Axiom CMM (new 2013)

- 1 – Brown & Sharpe Gage 2000 CMM

- 2 – Worm & Worm Gear Testers

- 1 – PECO ND 3000 CNC Gear Cheacker (New 2014)

- M 3540 QC Gear analyzer

- 1 – Pratt R Whitney Super Mic

- 1 – 4′ x 6′ Granite Plate

- 1 – Wilson 4 JR Hardness Tester